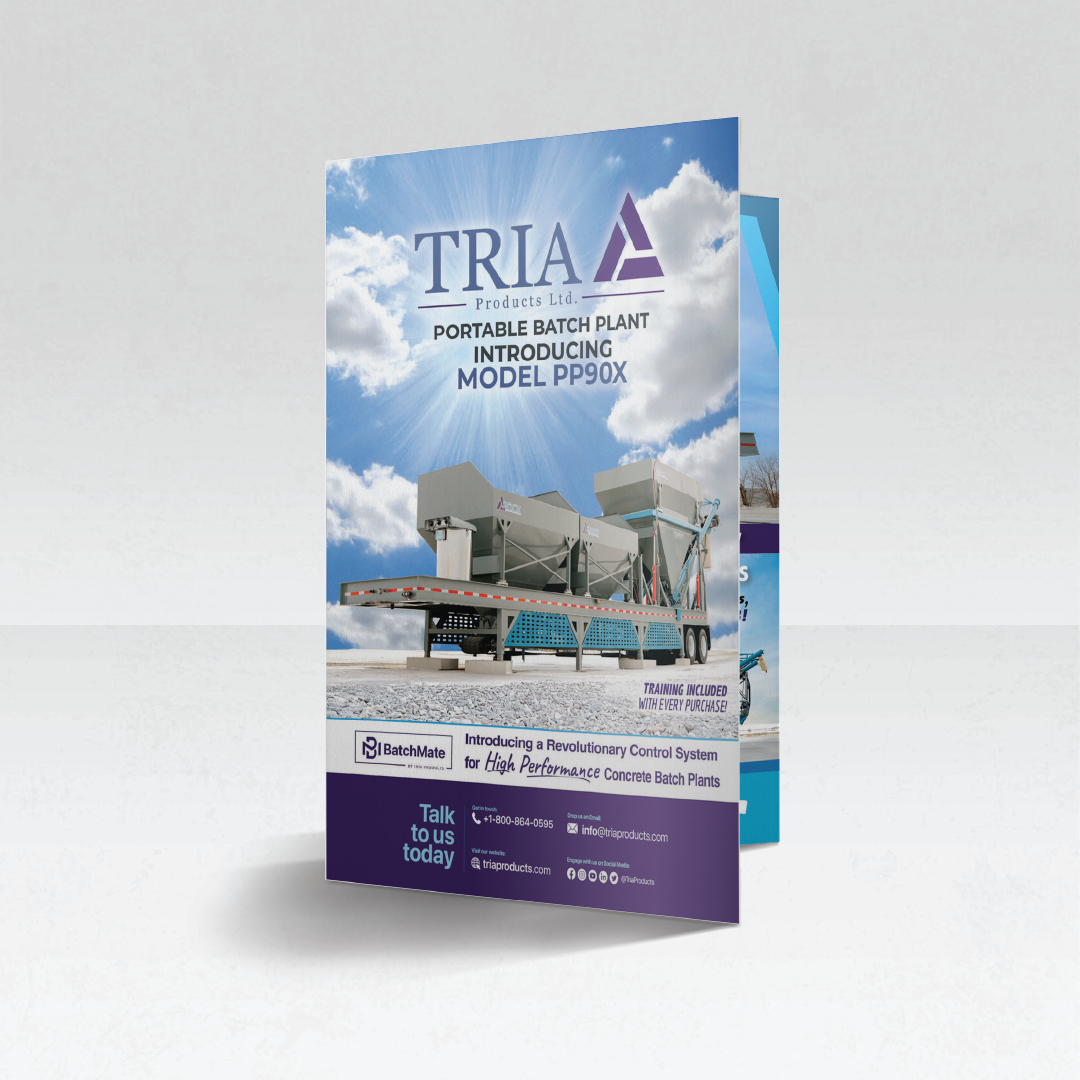

Portable Batch Plant

Model PP90X

The PP90X is paired with our BatchMate™ automated control system for precise and efficient batching. Its hydraulic lift-up cement silo is designed for front-loading trucks but can be used with any style, making loading operations fast and versatile.

Built to DOT standards, the PP90X can be set up in about 1 hour and moved easily from site to site. The lift-up design improves maintenance access while reducing downtime, setting a new standard for convenience and performance in portable batching plants.

Features

- Capacity: 110 yd³/hr • 85 m³/hr of concrete production

- Aggregate Hoppers: 55,200 lbs • 25,000 kg each for extended batching

- Cement Storage: 80,000 lbs • 36,300 kg • 40 tons total, with dual twin augers

- Transfer Conveyor: 30 in wide for efficient material handling

- Gates: Hydraulic-driven clam gates for reliable discharge control

- Automation: Paired with BatchMate™ for precise and efficient batching

- Fast Setup: Fully operational in about 1 hour

- Durable Build: Rugged design made to perform in harsh conditions