For over 20 years, Tria Products has been engineering and designing cutting-edge Concrete Batch Plants.

Model PP90X

Advanced batching system with integrated lift-up silo and BatchMate™ automation for maximum efficiency and storage capacity.

Capacity: 110 yd³/hr • 85 m³/hr

Model PP70A

Fully automated batching solution for consistent, high-quality concrete production with minimal operator input.

Capacity: 110 yd³/hr • 85 m³/hr

Model PP70M

Simple, rugged design for projects needing hands-on control, fast setup, and dependable mobility.

Capacity: 110 yd³/hr • 85 m³/hr

Model SP 100A

Heavy-duty stationary batch plant built for continuous, high-volume concrete production. Designed for long-term operation, the SP100A combines large storage capacity with reliable material flow, making it ideal for producers requiring consistent output day after day.

Capacity: 170 yd³/hr • 130 m³/hr

Model PP20

Our Portable Concrete Batch Plants are engineered for swift and effortless assembly.

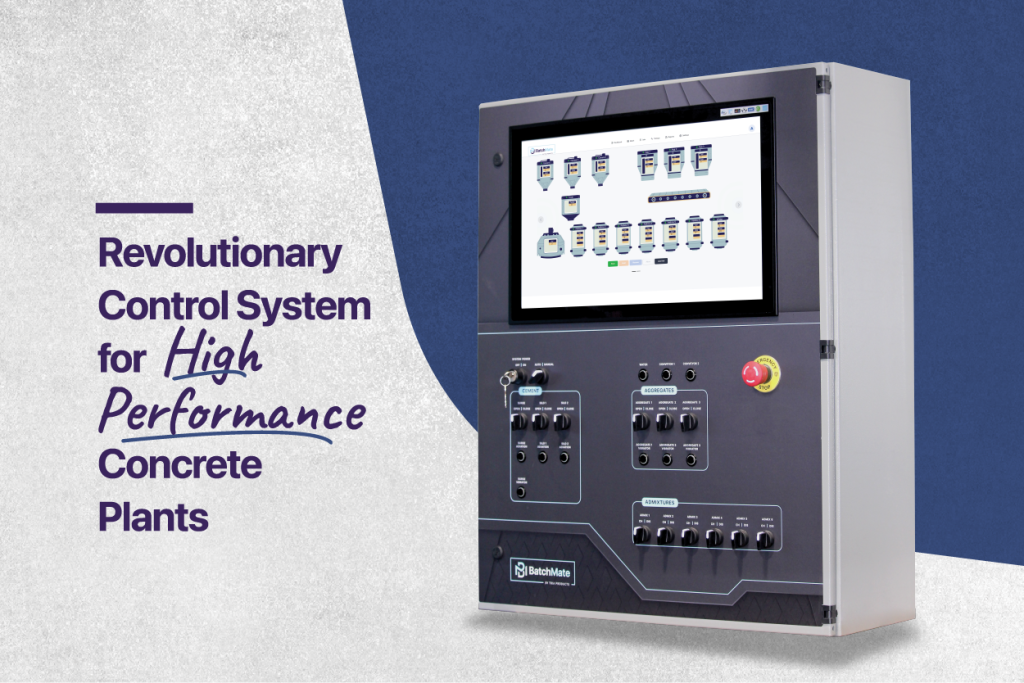

Revolutionary Control System for High Performance Concrete Plants

BatchMate(TM) empowers operators with unparalleled control and efficiency. Effortlessly monitor material levels across multiple hoppers, and manually adjust material quantities and moisture compensation for precise, real-time batching management.

Easy Customisation

Operators can effortlessly select preset mix recipes, enter moisture compensation manually, and press Start to initiate batching. With BatchMate(TM), switching between automatic and manual batching is seamless, enabling operators to easily adapt to varying batching needs and requirements.

Easy to Operate

BatchMateTM operates on the Windows 10 platform, ensuring ease of use even for operators with minimal tech experience. Additionally, BatchMate allows operators to control and monitor concrete batching remotely using other devices, providing unparalleled flexibility and convenience.

Features:

- Real-Time Monitoring

- Seamless Integration

- Safety First

- User-Friendly Interface

- Large Embedded Touchscreen Options,

- Remote Batching

- Physical and Virtual Manual Override Switches

- Empowers both Small and Large Plants

- Smart Learning of Material Correction