Automated Control Batching System

By Rice Lake Weighing Systems.

For more information or to request a quote call us today!

• Keyed power switch with internal circuit breaker.

• Keyed auto /manual control.

• Up to 8 auxiliary controls.

• All controls include status lights.

• Your choice of 6 single speed or 3 dual speed gate controls

• Status lights on each gate

• Weigh hopper discharge gate control

• Aggregate vibrator control

• Sand bin vibrator control

• Your choice of 4 cements with 2 dual speed fills or up to 4 single speed controls

• Status lights on each gate

• Cement bin aeration on 4 bins

• Weigh hopper discharge controls

• Weigh hopper vibrator control

• Fully integrated mixer controls

• Mixer start control

• Mixer stop control

• Mixer discharge control

• Water controls with status lights

• Metered water pulse status light

• Reservoir discharge control and empty status light

• Adjustable tail water discharge

• Automated and manual control of admixtures

• Pulse meters included, eliminating outboard control

• Up to 6 admixtures or colors

• Fill /feed control and status lights

• Discharge control and status lights

• Bottle empty status lights

Comprehensive plant control including status lights and manual override switches that can be configured in either momentary or maintain operation modes.

Manual Override Controls

• Dust collection system

• Alarm / horn

• Aggregate conveyor start /stop

• Air compressor start /stop

• Boot raise / lower

Status Lights Include:

• Aggregate conveyor running

• Load complete

• Cement gate closed

• Aggregate gate closed

• Out of tolerance

• Air pressure OK

ONBOARD REPORTING MODULE AVAILABLE

Easy Integration and Retrofit System Option

Elevate your concrete batch control easily as either a new installation, or a CB system upgrade. The CB-3 easily integrates with plant equipment and is an ideal replacement for existing concrete batch controllers. The retrofit option to upgrade a CB-2 with CB-3’s enhanced features and industrial PC is a smart solution for applications already familiar with automated concrete batching equipment and control.

• Onboard industrial PC interface

• 920i® digital weight indicator/controller

• One aggregate and one cement scale, optional weighed water scale

• Standard manual override controls

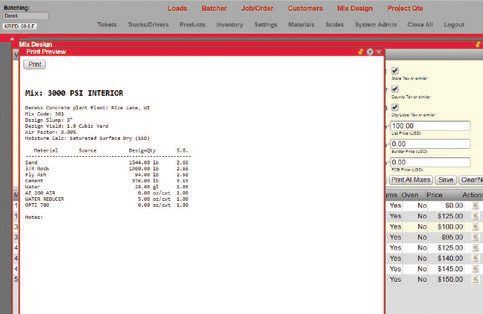

• Advanced batch tickets with configurable field printing

• Automatic aeration control for cement silos and weigh hoppers

• Automatic dust collection outputs

• Multiple free fall values per material

• Precision control of inching gates for aggregate and cement discharge

• Auto jogging gross, ideal targets and net mode batching

• Order-centric loading that also does load based or quick batch loading

• Material usaage by day/week/month/year and on-site inventory reporting

• Automatic pre-act compensation algorithm

• Pass code protection and multiple user roles for advanced documentation and security

• U.S. or metric units

• Automatic daily ticket and system backups

• FTP and remote support from factory capabilities

• 3 dual or 6 single speed aggregates

• 2 dual or 4 single speed cements

• Automatic dust collection outputs

• Optional dual moisture probe interface (supports 4-20mA)

• Optional weighed water

• Available in Spanish

• Manual discharge tracking (theft monitoring)

• Multiple browser-based windows and simultaneous processes to prepare the next batch while CB-3 is batching

Webmaster Ganica Design Solutions

The CB-3 concrete batching control system is fast, efficient and ideal for ready-mix and block plants. It is capable of controlling portable plants, stack-up plants, central mix, dry batch and pre-cast plants. From weighing raw material to automatic ticket printing and detailed reports, your entire operation is centrally controlled with the CB-3—all with the power of an industrial PC.

The CB-3 concrete batching control system is fast, efficient and ideal for ready-mix and block plants. It is capable of controlling portable plants, stack-up plants, central mix, dry batch and pre-cast plants. From weighing raw material to automatic ticket printing and detailed reports, your entire operation is centrally controlled with the CB-3—all with the power of an industrial PC.