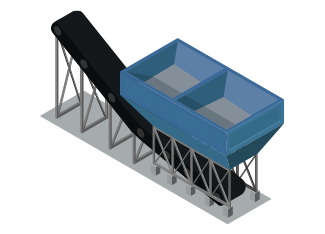

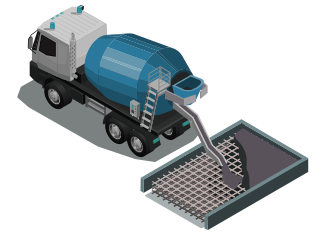

Automatic concrete batching systems

Choose between two options below

- CB-3 Automated Concrete Batching System

- Batch tickets and certificates

- Ability to reprint any batch ticket or certificate

- Material usage/inventory reports

- Mix design reports

- Batching statistics

- Truck monitoring

- Real-time batching visualization

- Efficient batching

- Multiple windows & simultaneous processes

- Learn More!

- 1280 Enterprise Series Concrete Batching System

- Customizable color touchscreen with graphical user interface

- User-defined softkeys, icons and graphics

- Tactile keypad for scale operations, numeric entry and navigation

- On-screen keyboard available during entry mode (or external keyboard)

- Built-in web server for remote access, systems integration and data monitoring

- Multi-language operation and text entry

- Three different enclosure types: universal with tilt stand, panel mount and wall mount

- Learn More!

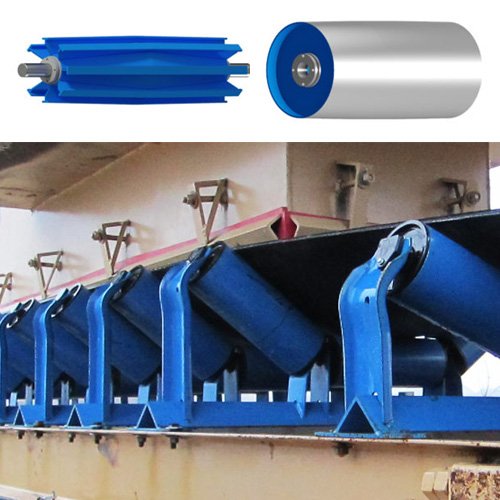

Parts & Accessories

©

2024

Tria Products LTD.

Webmaster Ganica Design Solutions